We have our own surface treatment plant, and the thickness of zinc layer meets the standard requirements. We can make authoritative inspection reports, including surface treatment such as hot galvanizing, Dacromet, electro galvanizing, boiling black, etc.

The outer hexagon screw is a matching nut used to fasten and connect two connected parts with through holes and components. Hex head screws are commonly used bolts. It is more important to use Class A and Class B outer hexagon. In addition, it is often used in the occasion of high assembly accuracy, large impact, vibration or cross rate load. Grade C outer 66 screws are used in situations where the surface is rough and the assembly accuracy is not required.

GB series, Q standard series, DIN German standard series, IFI American standard series, BS British standard series, JIS Japanese standard series, ISO international standard series, etc.

One of the standards for hexagon bolts is the level standard, which is divided into 4.8 and 8.8. These two levels are used more frequently in the market. Especially Grade 4.8 outer hexagon bolt. Because it is much cheaper than grade 8.8 hex bolts. Of course, it is more widely used. But for products with high requirements. Because of its high requirements in hardness and other aspects.

The material comes from a high-quality steel manufacturer, which can issue an authoritative material inspection report, including Q235, 35 #, 45 #, 345B, 40Cr, 35CrmoA, stainless steel 201, 304 and other special materials.

This requires the use of grade 8.8 hex bolts. Grade 8.8 outer hexagon bolt is harder in terms of hardness and screw torque. It is safer to use the product. Faster and more stable.

Poland, Russia, Algeria, Egypt, Ghana, Kuwait, the United Arab Emirates, Kazakhstan, Malaysia, Pakistan, the Philippines, South Korea, Myanmar, Thailand, Ukraine, Syria, India, the United States, Turkey, Brazil, Sri Lanka, Norway, etc.

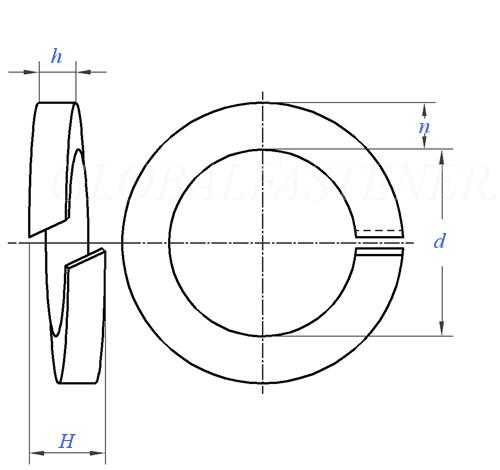

| Nominal Diameter | Φ2 | Φ2.2 | Φ2.5 | Φ3 | Φ3.5 | Φ4 | Φ5 | Φ6 | Φ7 | Φ8 | Φ10 | Φ12 | Φ14 | Φ16 | Φ18 | Φ20 | Φ22 | |

| d | min | 2.1 | 2.3 | 2.6 | 3.1 | 3.6 | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 10.2 | 12.2 | 14.2 | 16.2 | 18.2 | 20.2 | 22.5 |

| max | 2.4 | 2.6 | 2.9 | 3.4 | 3.9 | 4.4 | 5.4 | 6.5 | 7.5 | 8.5 | 10.7 | 12.7 | 14.7 | 17 | 19 | 21.2 | 23.5 | |

| n | Nominal Size | 0.9 | 1 | 1 | 1.3 | 1.3 | 1.5 | 1.8 | 2.5 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5 | 6 | 6 |

| max | 1 | 1.1 | 1.1 | 1.4 | 1.4 | 1.6 | 1.9 | 2.65 | 2.65 | 3.15 | 3.7 | 4.2 | 4.7 | 5.2 | 5.2 | 6.2 | 6.2 | |

| min | 0.8 | 0.9 | 0.9 | 1.2 | 1.2 | 1.4 | 1.7 | 2.35 | 2.35 | 2.85 | 3.3 | 3.8 | 4.3 | 4.8 | 4.8 | 5.8 | 5.8 | |

| h | Nominal Size | 0.5 | 0.6 | 0.6 | 0.8 | 0.8 | 0.9 | 1.2 | 1.6 | 1.6 | 2 | 2.2 | 2.5 | 3 | 3.5 | 3.5 | 4 | 4 |

| max | 0.6 | 0.7 | 0.7 | 0.9 | 0.9 | 1 | 1.3 | 1.7 | 1.7 | 2.1 | 2.35 | 2.65 | 3.15 | 3.7 | 3.7 | 4.2 | 4.2 | |

| min | 0.4 | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 1.1 | 1.5 | 1.5 | 1.9 | 2.05 | 2.35 | 2.85 | 3.3 | 3.3 | 3.8 | 3.8 | |

| H | min | 1 | 1.2 | 1.2 | 1.6 | 1.6 | 1.8 | 2.4 | 3.2 | 3.2 | 4 | 4.4 | 5 | 6 | 7 | 7 | 8 | 8 |

| max | 1.2 | 1.4 | 1.4 | 1.9 | 1.9 | 2.1 | 2.8 | 3.8 | 3.8 | 4.7 | 5.2 | 5.9 | 7.1 | 8.3 | 8.3 | 9.4 | 9.4 | |

| per 1000 units ≈ kg | 0.033 | 0.05 | 0.053 | 0.11 | 0.12 | 0.18 | 0.36 | 0.83 | 0.93 | 1.6 | 2.53 | 3.82 | 6.01 | 8.91 | 9.73 | 15.2 | 16.5 | |

| Nominal Diameter | Φ24 | Φ27 | Φ30 | Φ36 | Φ39 | Φ42 | Φ45 | Φ48 | Φ52 | Φ56 | Φ60 | Φ64 | Φ68 | Φ72 | Φ80 | Φ90 | Φ100 | |

| d | min | 24.5 | 27.5 | 30.5 | 36.5 | 39.5 | 42.5 | 45.5 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | 81 | 91 | 101 |

| max | 25.5 | 28.5 | 31.7 | 37.7 | 40.7 | 43.7 | 46.7 | 50.5 | 54.5 | 58.5 | 62.5 | 66.5 | 70.5 | 74.5 | 82.5 | 92.5 | 102.5 | |

| n | Nominal Size | 7 | 7 | 8 | 10 | 10 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

| max | 7.25 | 7.25 | 8.25 | 10.25 | 10.25 | 12.25 | 12.25 | 12.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | |

| min | 6.75 | 6.75 | 7.75 | 9.75 | 9.75 | 11.75 | 11.75 | 11.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | |

| h | Nominal Size | 5 | 5 | 6 | 6 | 6 | 7 | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| max | 5.2 | 5.2 | 6.2 | 6.2 | 6.2 | 7.25 | 7.25 | 7.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | |

| min | 4.8 | 4.8 | 5.8 | 5.8 | 5.8 | 6.75 | 6.75 | 6.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | |

| H | min | 10 | 10 | 12 | 12 | 12 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| max | 11.8 | 11.8 | 14.2 | 14.2 | 14.2 | 16.5 | 16.5 | 16.5 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | |

| per 1000 units ≈ kg | 26.2 | 28.7 | 44.3 | 67.3 | 71.7 | 111 | 117 | 123 | 182 | 193 | 203 | 218 | 228 | 240 | 262 | 290 | 318 | |

1. Professional online service team, any mail or message will reply within 24 hours.

2. We have a strong team provide wholehearted service to customer at any time.

3. We insist on Customer is Supreme, Staff toward Happiness.

4. Put the Quality as the first consideration.

5. Advanced production equipment, strict quality testing and control system to make sure superior quality.

6. Good quality: good quality can be guaranteed, it will help you keep the market share well.